Products

Products in our catalogue

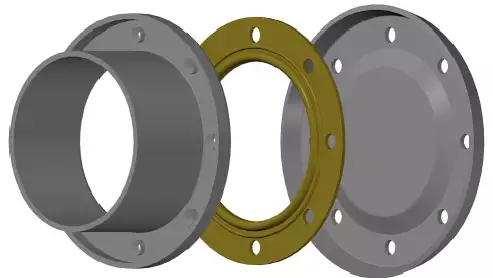

Our dished ends are produced on automatic lines and robotic islands that allow us to carry out the trimming and edging of the parts after the cold forging phase.

We process sheets in both carbon and stainless steel or other types of metal alloys up to a maximum diameter of 2000 mm and a thickness that can vary from 1 to 7 mm depending on the type and intended use of the bottoms.

In addition to standard products, we can also print customised bottoms from customer drawings.

Our automated systems are very flexible and can also be used for series stamping of sheet metal parts for metal components used in a wide variety of industries.

The technology of our presses from 1,000 to 16,000 kN allows the production of even complex products by means of traditional cold stamping or deep drawing.

Unless otherwise stated, the general tolerances applicable to products are those shown in this table.